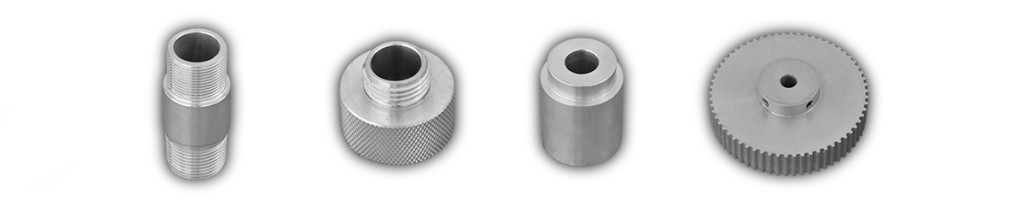

CNC MACHINING SERVICES

As a one-stop shop for turn-key parts, the Super Vac Foundry offers CNC machining services. With four CNC machining centers, customers can rely on precision, repeatability and more than 35 years of expertise. And while many components are cast in our foundry, Super Vac can machine other materials, including plastics, steel and stainless steel.

A look at super vac's machining center lineup

trumpf trulaser 2030

a HAAS VF3 vertical machining center

With a spindle speed of 7,500 RPM, a 48” x 18” table that moves on an X and Y axis and a 24-pocket tool carousel, this center can mill most any material to your specifications.

a HAAS VF7 vertical machining center

With a 7’ table that moves on an X and Y axis, this vertical machining center accommodates larger parts. The VF7 features a 10,000 RPM spindle and a 24-pocket tool carousel.

a HAAS SL 30HP

CNC LATHE machine

Featuring a 30HP, 3,400 RPM spindle and a 12-piece tool turret, Super Vac’s CNC lathe machine can turn, drill and thread parts to customer specifications.

A HAAS CL-1 Chucker LATHE machine

The CL-1 is an ultra-compact CNC chucker lathe that comes with an 8-station automatic turret, making it an excellent choice for some of Super Vac's smaller parts.

your machine shop denver resource