PERMANENT MOLD CASTING

COLORADO’S ONLY PERMANENT MOLD CASTING FOUNDRY

The Super Vac Foundry’s permanent mold casting process uses reusable, “permanent” molds, usually made from gray cast iron. Using a permanent mold machine, Super Vac uses gravity to fill the mold with molten metal. This process delivers higher production rates, finer grain structure and more dimensional accuracy than other casting methods and is ideal for large production runs due to higher tooling costs.

CASTING METALS

Don’t let the word “permanent” mislead you. While these permanent molds are used repeatedly, permanent molds have a mold life, which is dependent on mold material, mold temperature and pouring temperature. Typically, a mold can be reused several thousand cycles. To help preserve the mold, this process is typically limited to low-melting-point casting metals. For that reason, we use these casting metals:

ALUMINUM

319 Aluminum (319SR)

356 Aluminum (356.2)

STEP 1 PERMANENT MOLD PRE-HEATING

The tilt pouring machine is set in a horizontal position and preheated to 300-700°F for mold preparation. During this step, the permanent mold halves and any applicable cores are inserted and closed mechanically inside the casting machine.

STEP 2 THE MOLTEN ALLOY IS POURED

The molten alloy, heated in a separate furnace, is poured into the machine’s pour cup. The machine is then titled vertically, causing the molten metal to flow into a gating system that controls the flow of metal into the cavity for consistent results.

STEP 3 THE CASTING IS REMOVED

Once the casting solidifies (in roughly 140 seconds), the mold is opened and the casting is removed. Any excess metal is cut from the part using a band saw and returned to the melting furnace to be used in the next casting.

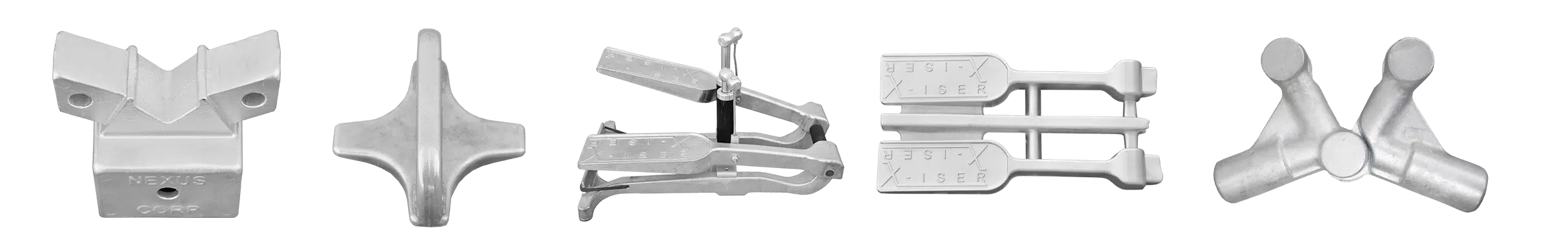

PERMANENT MOLD CASTING EXAMPLES